Kinugawa

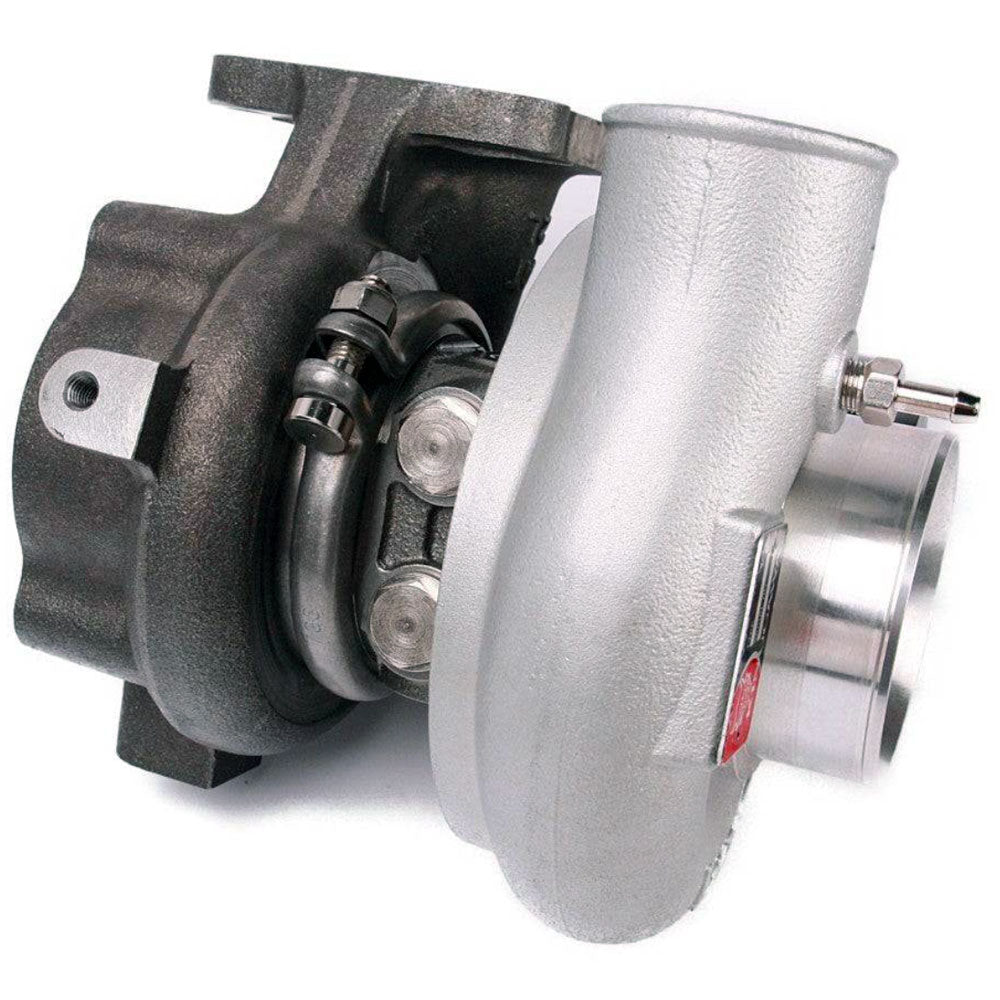

TD05H Bolt On Turbo for Toyota Landcruiser 78/79/80/100 Series (1HD)

TD05H Bolt On Turbo for Toyota Landcruiser 78/79/80/100 Series (1HD)

Couldn't load pickup availability

Now Accepting

Collapsible content

Description

Bolt on replacement for the CT26 single-scroll turbo found on the 1990's and early 2000's Toyota Landcruiser with the legendary 1HD Turbo Diesel motors. This range of turbochargers is a great value upgrade for those wishing to push further than what the CT26 turbo frame can offer. Aftermarket intake systems and intercooler piping is required to install these turbos. Available as well with a 3" V-Band turbine housing for those wishing to have a new exhaust system fabricated.

Fitment Information

Other turbocharger specifications are listed below. Please contact us for any additional information or clarification.

| Application |

1990-1995 Toyota Landcruiser 80 Series (1HD-T) |

| Wastegate System |

Internal |

| Compressor Housing Size | 0.60 a/r |

| Compressor Housing Inlet Type | Standard or Anti-Surge |

| Compressor Housing Inlet Size | 76mm/3" or 101mm/4" (aftermarket intake required) |

| Compressor Housing Outlet Size | 2" (aftermarket intercooler piping required) |

| Turbine Housing Size |

6cm (.41 a/r)* or 7cm (.49 a/r) (*aftermarket dump-pipe required) |

| Turbine Housing Inlet |

Toyota Single Scroll CT26 4-Bolt or T3* (*aftermarket manifold required) |

| Turbine Housing Outlet |

Toyota Single Scroll CT26 4-Bolt, 2.5" V-Band* or 3.0* V-Band (*aftermarket dump-pipe required) |

| Cooling System | Oil and Water Cooling |

Collapsible content

TD05H Compressor Wheels

The TD05H is available with a huge range of compressor wheels to dial in your desired peak horsepower and power delivery. Smaller wheel size will allow for faster spool but will sacrifice top-end power.

| 16G | 18G | 16KX | 20G | 18KX | |

|---|---|---|---|---|---|

| Inducer | 48.3mm | 50.3mm | 52.3mm | 52.5mm | 55.0mm |

| Exducer | 68.0mm | 68.0mm | 68.0mm | 68.0mm | 75.0mm |

| Wheel Options | Cast 6+6, Billet 6+6, Billet 11+0 | Cast 6+6, Billet 6+6, Billet 11+0 | Billet 7+7 | Cast 6+6, Billet 6+6, Billet 11+0 | Billet 7+7 |

Each size wheel is available in cast or billet materials with multiple blade types for the billet wheels. Choose the best option for your budget and application.

| Wheel Design |  |

|

|

|

|---|---|---|---|---|

| Material | Cast | Billet | Billet | Billet |

| Blade Design | 6+6 | 6+6 | 11+0 | 7+7 (KX Wheels Only) |

| Manufacturing Process | Casting | CNC Machined | CNC Machined | Point Milling CNC Machined |

| Benefit | Low-End Torque | Low-End Torque | Top-End Speed | Low-End Torque + Top-End Speed |

TD05H Turbine Wheels

The TD05H turbine wheel is available in multiple configurations to suits your budget and application. The STS (Superior Turbine Strike) turbine wheel is 5-8% faster to build a boost and, at higher RPM, prevents choking easier because due to its lower inertia and restriction when compared with an 11 or 12 blade turbine wheel. The STS 55 builds on this with a new 5+5 blade design allowing for even faster spool times and higher exhaust gas flow.

| Wheel Design |  |

|

|

|---|---|---|---|

| Blade Design | 12-Blade | 9-Blade | 5+5 Blade |

| Material | Inconel 718 | Inconel 718 | Inconel 718 |

| Inducer | 56.0mm | 56.0mm | 56.0mm |

| Exducer | 49.1mm | 49.1mm | 49.1mm |

TD05H Specifications

Other turbocharger specifications are listed below. Please contact us for any additional information or clarification.

| Turbocharger Frame | TD05H |

| Compressor Wheel Size (Inducer/Exducer) | 16G (48.3/68.0mm), 18G (50.3/68.0mm), 16KX (52.3/68.0mm), 20G (52.3mm/68.0mm), 18KX (55.0/75.0mm), 60-1 (60.0mm/76.0mm) |

| Turbine Wheel Size (Inducer/Exducer) | 56.0mm/49.1mm |

| Turbine Wheel Type | 12-Blade, 9-Blade STS, 5+5 Blade STS 55 |

| Bearing System | Journal Bearing (Performance Thrust Bearing Kit) or Dual ceramic ball bearing system |

| Maximum Boost Pressure | 2.8 Bar (40 psi) |

| Recommended Boost Pressure | 1.5 Bar (21 psi) |

| Horsepower Range* | 300-450HP |

| Condition | Brand New, CHRA Balanced |

| Warranty | 12 Months |

*Horsepower will depend on selected options above and vehicle application and modifications

Included Hardware

A universal set of oil/water lines, fittings and hardware is included and listed below. These will suit a variety of applications however we can often include different components for your application. Please contact us when purchasing to discuss.

Hardware:

- 1 x Turbine Inlet Gasket (to suit selection)

- 1 x Turbine Outlet Gasket (if suitable for selection)

- 1 x Turbine Outlet V-Band Clamp (if suitable for selection)

- 2 x Oil Drain Hose Barb Fitting Bolts

Hoses:

- 1 x -4AN Strainless Steel Braided Oil Supply Hose

- 2 x -6AN Strainless Steel Braided Coolant Supply and Return Hoses

Oil Fittings:

- 1 x -4AN Strainless Steel Braided Oil Supply Hose

- 1 x Bolt-On Oil Drain Hose Barb Fitting

- 1 x Oil Drain Barb Gasket

- 1 x -4AN Turbo Oil Feed Banjo Fitting with Banjo Bolt

- 1 x 1/8" NPT to -4AN Hose Tee Fitting

Coolant Fittings:

- 2 x -6AN Male Turbo Coolant Fittings

- 2 x -6AN Male to Hose Barb Fittings

Important Notes When Upgrading to a New Turbo

Turbochargers are seemingly simple components but there are many external influences that can affect its performance and reliability as well as that of your engine and drivetrain. We have provided a list below with some important things to consider when upgrading to a new high performance Turbo.

Replacing a Faulty Turbocharger

Turbos rarely fail on their own accord and failures are typically caused by a problem elsewhere in the engine bay. If replacing a faulty turbocharger it is recommended to perform some investigation as to why the old turbo failed. If a pre-existing problem caused the old turbo to fail it is possible this will cause a premature failure of the new unit as well.

Installing a Turbocharger on a Freshly Built Engine

One of the most common situations we experience is a turbocharger failing shortly after startup, on the dyno or during the first few months of operation. This can be down to either improper pre-start preparation or due to the engine block and surrounding components not being correctly cleaned after assembly. Special attention must be given to ensuring all intake, exhaust, oil and coolant passages in the engine are cleaned of debris before installing the turbo. Should any contaminants make their way through the turbo it can cause almost instant failure.

Knock-On Effects of Increasing Performance

When installing a high performance turbo the existing powertrain will not operate in the same manner. Temperatures and pressures of almost all aspects of the engine will increase and if adequate measures are not taken it may cause turbocharger failure and/or engine failure.

An example of this would be increased crankcase pressure. Due to this pressure increasing it can increase blow-by and reduce the flow of oil from the turbo drain back to the oil sump. Additional blow-by will result in oil deposits in the intake, turbo and intercooler system. Reduced oil drain can cause oil to pool in the turbo cartridge and cause smokey exhaust and bearing failure. It is recommended to upgrade the engine breather system and install oil catch cans or air/oil separators to mitigate these potential problems.

New Turbo Pre-Start Checklist

The first stages of running a turbo after a new installation is crucial to its performance and reliability. We highly recommend looking over the following checklist after installation but before starting the engine for the first time:

Oil Supply

Oil is crucial to the operation of a turbocharger as it can see rotational speeds of over 100,000rpm. Failure to provide a clean and consistent oil supply can cause an immediate failure. If replacing an old turbo it is recommended to replace the oil feed hose and any fittings or filters between the engine and turbo. Certain vehicles run banjo fittings with an internal filter screen which should be replaced when installing a new turbo and checked regularly.

Oil Return

Whilst a turbo needs oil to operate reliably it also cannot have too much inside the bearing cage and must be able to exit from the turbo freely. Special attention must be paid to the oil return/drain hose to ensure it is free of debris and oil can move easily. If replacing an old turbo it is recommended to replace this hose. If oil cannot exit the turbo it can pool inside and cause premature bearing failures leading to oil leaking into the compressor or turbine housing.

Intake and Exhaust Piping

Ensuring all piping before and after the turbocharger is leak free and secure will help prevent turbocharger over-speed conditions and producing excess heat. A small boost or exhaust leak will mean the turbo has to work harder to hit target boost and could cause failures to the turbo or surrounding components.

Wastegate Setup

For internally wastegated turbos please ensure adequate pre-load on the wastegate actuator rod. A general rule of thumb is to have the clevis hole 1/4 to 1/2 a hole off the centre of the pin so that the rod must be "stretched" to slip over, creating tension and ensuring the wastegate flap is firm against the housing.

For both internally or externally wastegated turbos ensure the correct spring is fitted inside and a hose is connected from the compressor cover to the top of the wastegate housing.

Turbocharger Priming

After all above points have been checked over and the car is ready to start it is recommended to prime the turbo with fresh oil first. This can be achieved multiple ways but an example procedure is as follows:

- Install oil feed line to engine but leave the turbo end of the line disconnected

- Place the oil feed line fitting that's not connected in a receptacle to catch any oil

- With engine in a NO-START condition, crank engine WITHOUT firing until oil drains freely from the oil feed line

- Connect oil feed line to turbo (with restrictor if provided), and install the oil drain hose, leaving the engine end of the turbo oil drain hose disconnected and directed into a suitable receptacle

- With engine still in a NO-START condition, crank the engine WITHOUT firing until oil flows freely from the turbo oil drain

- Connect oil drain, and dispose of any oil caught in the receptacle - your turbocharger is now primed with oil and ready for first start

First Start

- Start the engine and allow to idle for approximately 3 minutes to purge any air in the system

- Check all unions and fittings are tight and free from leakage

- Check all hoses are routed away from heat sources and any potential chafing risks

- Stop engine, re-check engine oil level and top up as necessary

- Your turbocharger is now ready for use

Warranty Information

If any products are proven to Kinugawa Turbo Systems’ satisfaction to have been defective at the time of sale, We will make an appropriate adjustment in the original sales price of such product or at Kinugawa Turbo Systems’ election, replace the defective product. Kinugawa Turbo Systems shall provide information for limited warranty extended to the consumer of

commodities. Said warranty applies only to “completed” and “unaltered” turbochargers only (spare parts exculded) sold by Kinugawa Turbo Systems; any alterations made to the completed products by any party other than Kinugawa Turbo Systems shall negate such warranty. Warranty shall cover 100% of parts for one (1) year from the date of purchase. All other products sold by Kinugawa Turbo Systems shall be covered by an “exchange” of the same product within seven (7) days from the date of purchase and provided that the product to be exchanged has not been used in any manner.

1.1. For none- Kinugawa Turbo Systems branded and completed turbo units, warranties expressed or implied are represented by the manufacture of the product and not Kinugawa Turbo Systems.

1.2. Kinugawa Turbo Systems warrants to the purchaser of its products that will during the warranty period and subject to the limitations and exclusions comply with all applicable specifications and be free from defects in materials and artistry. Kinugawa Turbo Systems’ liability is limited to the repair or replacement, at our option, of any warrantable product returned prepaid with complete service history, if found by Kinugawa Turbo Systems to be defective in material or artistry. All replacement units shall be rebuilt units similar in quality to the unit replaced.

1.3. Kinugawa Turbo Systems’ warranty shall not apply to any unit that has been improperly stored or installed, subject to misapplication, improper operating conditions, accidents or neglect, or has been poorly repaired or altered or otherwise mistreated in the field. Unauthorized disassembly will void all warranty consideration. TURBOCHARGER WARRANTY SHALL NOT APPLY TO ANY TURBOCHARGER THAT

SHOWS EVIDENCE OF (1) Hot shut down. (2) Insufficient lubrication. (3) Oil Contamination/ Foreign object in lubricating oil. (4) Any damage to either the compressor wheel or the turbine wheel caused by a foreign object. (5) Over-boosting (over Kinugawa turbocharger standard pressure of 1.2 bar or 17psi).

1.4. Kinugawa Turbo Systems shall not be liable to purchaser under any circumstances for any special, incidental or consequential damages, including without limitation, damage to or loss of property other than for turbocharger products; costs incurred in installation, repair or replacement; lost profits, revenue or

opportunity; loss of use; damages resulting from or related to downtime of turbocharger products; the cost of replacement transportation, power or compression; the cost of substitute products; or claims of Distributor's customers for such damages, howsoever caused, and whether based on warranty, contract and/or tort(including negligence, strict liability or otherwise).

1.5. The obligations in connection with the design, manufacture, sale, delivery, and/or use of Kinugawa Turbo Systems’ turbochargers and related parts and/or services shall in no circumstance exceed in aggregate a sum equal to the amount paid to Kinugawa Turbo Systems for turbocharger products subject to customer's warranty claims.

2.TURBOCHARGERS FOR RACING OR COMPETITION USE

2.1 Turbochargers used for any form of racing or competition and/or set to run higher than standard boost pressure are supplied in good faith and on the understanding that no guarantee is given in respect of performance or reliability of the product, either by the manufacturers or Kinugawa Turbo Systems.

2.2 Kinugawa Turbo Systems cannot be held responsible for personal injury or damage caused to the engine or vehicle by a failed turbocharger.

3. OTHER WARRANTY CONDITIONS

3.1 The turbocharger must be fitted to an engine that is in good working order so that the operation of the turbocharger is not prejudiced.

3.2 The engine oil, oil filter, and air filter must be changed at the point of turbocharger fitment, using only components and materials approved by the vehicle manufacturers. In the case of petrol engine turbochargers, Kinugawa Turbo Systems only recommends fully synthetic oil with an SAE rating of 10W-40 or higher and which exceeds the following specifications: SH/CD or CCMC G5/PD2 unless otherwise stated by the vehicle manufacturer. For further information

and advice, please contact our Technical Sales Team.

3.3 The purchasers/installers shall satisfy themselves that all reasonable steps have been taken to ensure that any original cause of turbocharger failure has been eliminated and that the turbocharger is correct for the application,

and is fitted entirely in line with the engine manufacturer’s recommendations.

3.4 Warranty may be denied in the event of either the turbocharger or the engine being modified to increase power output if this modification is prejudicial to the performance of the turbocharger.

3.5 Under no circumstances should a vehicle be used if a turbocharger problem is suspected, as this could cause further damage to the turbocharger and/or engine.

4. LIMITATION AND EXCLUSION OF LIABILITIES

4.1 Kinugawa Turbo Systems Performance Kits are professional aftermarket products only designed for certain racing vehicles driven on particular racing tracks and shall only be used on racing vehicles that will never be driven on public roads or highways. Kinugawa Turbo Systems Performance Kits are not legal for the use in vehicles on public roads or other road to which public road law applies. Any vehicle modifications using Kinugawa Turbo Systems Performance Kits are AT YOUR OWN RESPONSIBILITY and AT YOUR OWN RISK. Only use Kinugawa Turbo Systems Performance Kits in compliance with all applicable laws, regulations and ordinances (including but not limited to emission, noise, operating license, performance, safety and type-approval aspects). A vehicle modification using Kinugawa Turbo Systems Performance Kits may particularly affect or void a vehicle’s warranty, operating license or type-approval. Moreover, only use Kinugawa Turbo Systems Performance Kits in compliance with all applicable racing and racing track provisions. It is YOUR OWN RESPONSIBILITY AND RISK to ensure that your Kinugawa Turbo Systems Performance Kit fits your vehicle and area of application. YOU MUST ENSURE LAWFUL AND SAFE OPERATIONS AT ANY TIME. You should particularly consult the owner’s manual and service manual of your vehicle. You should also contact your vehicle’s manufacturer to determine what effects modifications may have on important aspects such as safety, warranty, performance, etc. Only install and use Kinugawa Turbo Systems Performance Kits if you have fully read and understood this important safety information and if you fully agree with the terms and conditions set forth therein.